Metal wire, metal strips,twisted basalt fibers, twisted glass

fibers, twisted carbon fibers, various chemical twisted fibers,

optical fibers --- surface treatment coating line, functional

coatings line, optical functional coating line, continuous wire and

strip vacuum deposition equipment, nanometer thin film deposition

line

1. Coating Films:

1.1 Conducitve metals: Al, Cr, Cu, Ti, Zr, Ag, Au, Ni etc.

1.2 Non-conductive metal based films: Tantalum(Ta ), TaN, Ta2O5,

Silicon (SiOx) , Indium (In), Niobium (Nb) TiNbN etc.

Application

1. Metal conductive filaments

2. Metal coil strips, thickness is less than 1mm

3. Fiber-Optic Cables

4. Chemical fiber wires

5. Chemical fiber line

6. Glass yarns and carbon yarns copper coating

7. Carbon yarns and glass yarns aluminum coating

9. PVD silver plated copper wire,

10. Silver plated fiber- optic cable

11. Gold plated wire machine

12. Silver-plated copper strip

13. Silver plating on copper , bronze and brass cables

14. New Multi-Layer Coating Line for Copper wire and strips

15. Silver Plating Machine for Fiber Optical Cable

Technical Background

After decades of research and development, vacuum coating has been

quite a mature film deposition treatment which has a positive

prospect applications in various industries. It requires a

comprehensive technologies to apply the vacuum coating technique to

continuous wires and strips, which can modify the surface

characteristics and functions, its significant lightweight

performance makes an advantage for artificial intelligence devices.

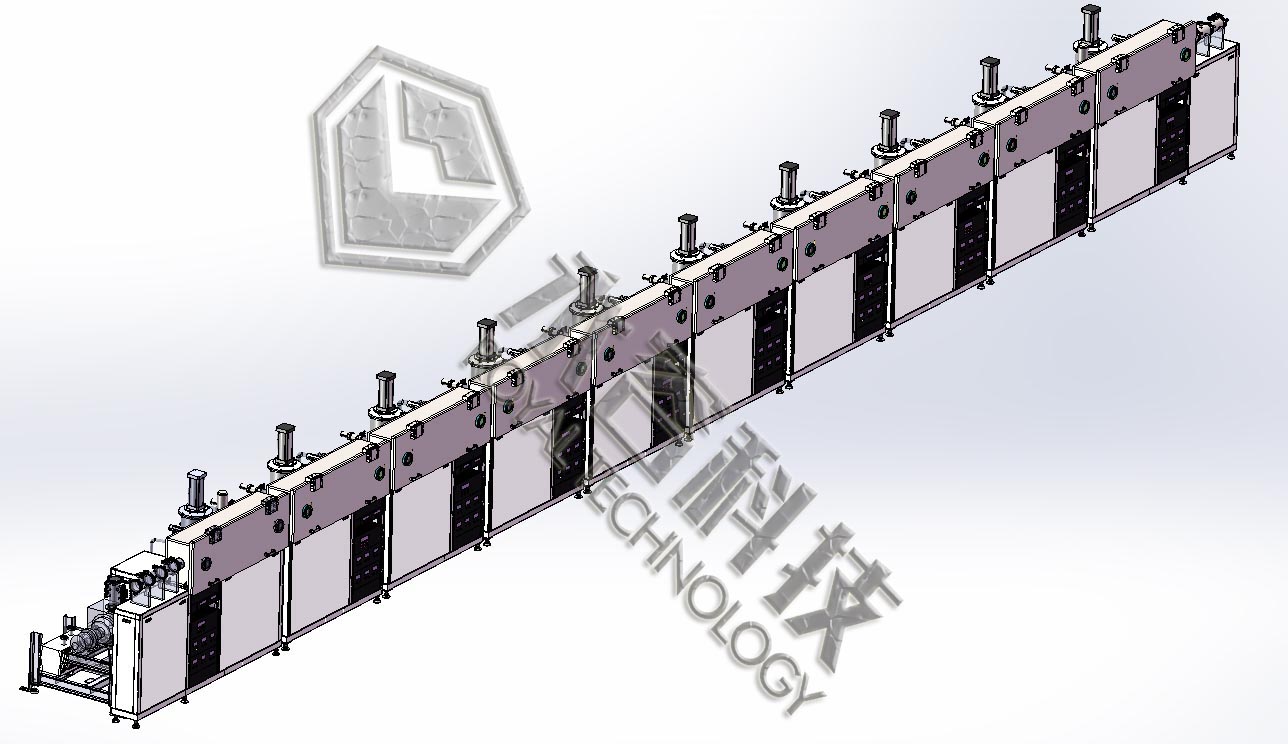

Types of the existing vacuum coating production line for wires and

strips substrates

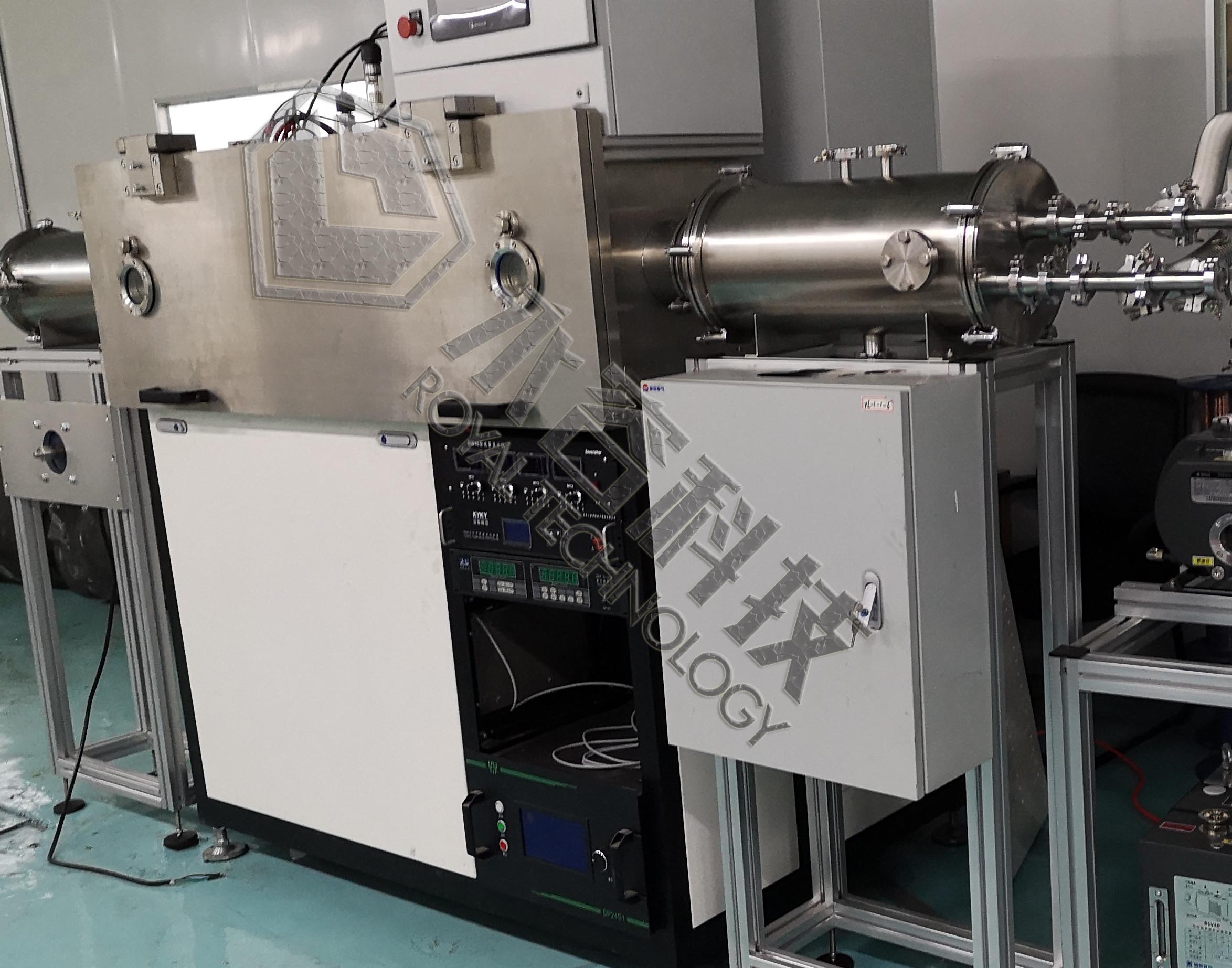

(1)Separated type

(2) Air-to Air,full continuous coating type

The Air-to Air full continuous coating line is a completed

continuous coating process processes which including cleaning

pre-treatment in the atmosphere environment, and then the

substrates ( strips or wires) enters into the vacuum chamber to get

metal films deposited, in then end it back to atmosphere

environment again through buffering chambers.

The coating line key structural modules:

A: Substrates (strips or wires) cleaning pre-treatment module

B: Cooling down module

C: Annealing module

D: Film deposition chamber

E: Loop devices and vacuum buffering chamber.

The whole coating line’s structure, operation and control system is

more complex, extremely high investment but the advantages of high

output and sharping down production cost efficiently make it is

very attractive for manufacturers.

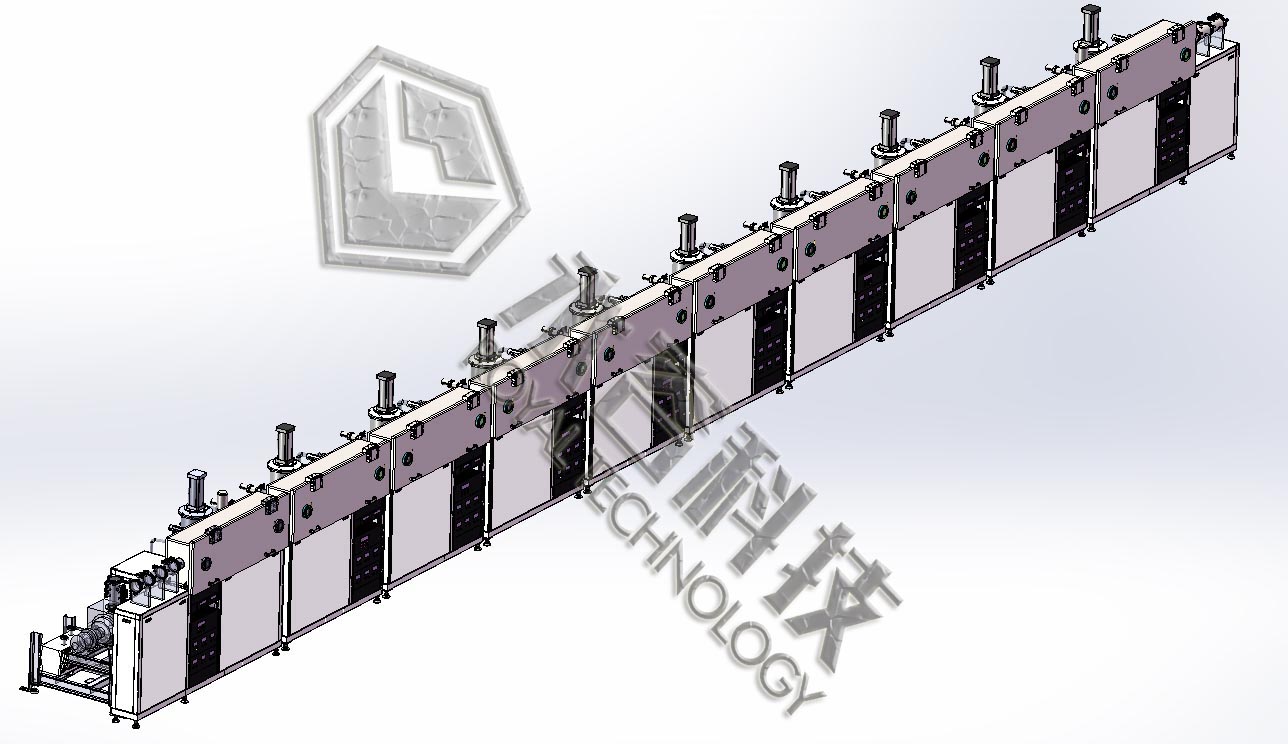

Desgin Features:

1. Roll to Roll + Inline sputtering system

2. High precision control

3. Unlimited chambers based on the coating process's demand;

4. Multiple coating technologies

5. Flexible combination: pre/post treatment chambers, buffing

chambers, deposition chambers (PVD, PECVD, CVD etc.)

6. Various metal layers deposition.

7. Modular standard design and fabrication

8. Quick installation and maintenance

9. IPC operation and control system

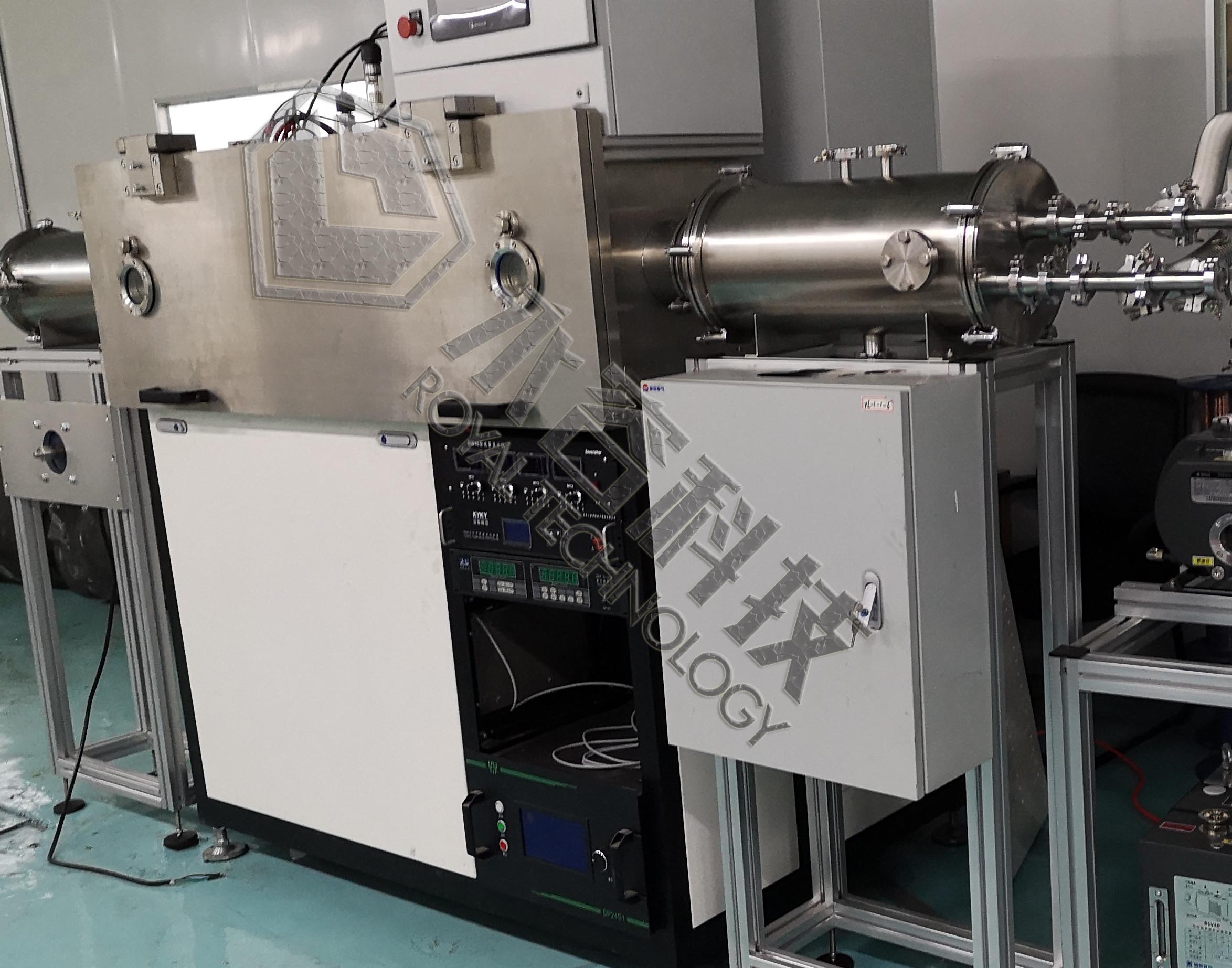

Support and Services:

Our technical support team is available 24/7 to answer customer

inquiries, provide technical advice and troubleshooting assistance.

Our technicians are highly experienced in the operation and

maintenance of Roll to Roll Coating Machines and are available to

guide customers through the installation, set-up, and operation of

the machines.

We also provide maintenance and repair services for our machines,

offering preventive maintenance schedules, spare parts, and

emergency repair services.